If you live near the ocean, you already know the truth: coastal air is beautiful… and brutal. It eats paint, it stains hardware, it seizes hinges, and it turns “good enough” metal into a rust problem faster than anyone expects.

That’s why “coastal window bars” is not a normal home-security search. It’s a specific pain. People typing that phrase are saying:

I want security bars that won’t rust in salt air.

I don’t want to replace them next year.

I want something strong, clean-looking, and safe.

I want a real solution—not a temporary fix.

This guide is built exactly for that moment. It’s written to help you make the smartest decision for a coastal climate, and it’s designed to be the single page you can come back to whenever you’re comparing finishes, materials, installation methods, and long-term durability.

And yes—if you want a system engineered around real-world window sizes and coastal durability, you’ll find the full SWB specs, options, and resources at:

If you only read one section, read this:

1) Coastal air accelerates corrosion because salt (chlorides) + humidity create a conductive film on metal.

2) “Painted steel” alone often fails early in coastal conditions, especially if the coating gets nicked or scratched.

3) The best-performing approach for many coastal homes is a layered protection strategy (a true system), not just a pretty finish.

4) Hardware matters as much as the bars. Coastal corrosion often starts at screws, anchors, and joints.

5) Installation choices matter: exterior installs face more salt exposure; interior installs can extend coating life.

6) A modular system can be a huge advantage when you have multiple windows, odd sizes, or you want the ability to adjust and replace individual components.

Want a solution built for real homes—not one-off custom metalwork that’s expensive and hard to maintain?

Start with SWB’s resources and product details at www.securitywb.com

(The part nobody explains clearly)

Rust isn’t “just old metal.” Rust is chemistry, and coastal environments create the perfect conditions for corrosion to accelerate:

• Salt particles float in the air (especially near shorelines). They settle invisibly on metal surfaces.

• Salt attracts moisture from the air. Even when it’s not raining, salt can keep metal surfaces slightly damp.

• That moisture layer becomes conductive, allowing corrosion reactions to happen faster.

• Coastal homes often experience cycles of wet + dry + wet + dry (marine mist at night, sun during the day). Those cycles are a corrosion engine.

In plain English:

Salt + moisture + oxygen = faster corrosion.

And coastal climates deliver those three ingredients daily.

The biggest mistake homeowners make is buying “normal” window bars and expecting them to last like they would inland. They might look great in month one… then start failing where you can’t see it: around screws, under coatings, inside seams, and at contact points.

When a product is truly suited for coastal use, it’s not one feature—it’s a system. Coastal-ready window bars should address:

1) Base material strength (security is still the first job)

2) Coating/finish durability (resistance to salt air exposure)

3) Hardware selection (fasteners and anchors that won’t become the weak link)

4) Design geometry (avoiding places where salty moisture sits and starts corrosion)

5) Installation strategy (interior/exterior placement, standoffs, and sealed contact points)

6) Maintenance reality (easy cleaning, quick inspection, simple touch-ups)

SWB’s approach is built around solving the real-life homeowner problem:

You want serious security, but you also want durability, flexibility, and an installation that fits real windows (including odd sizes) without turning your home into a permanent construction project.

For exact SWB models, sizing guidance, and options, go straight to:

www.securitywb.com

A common shopping trap looks like this:

• You see bars that look heavy-duty.

• They’re “powder-coated” or painted black.

• The photos look great.

• The price feels reasonable.

• You buy them.

Then the first coastal season happens.

Here’s what many people don’t realize: in coastal conditions, the coating is not just for looks—it is a barrier. And barriers fail when:

• The coating is thin or poorly bonded

• The surface prep was weak before coating

• The bars get nicked during installation

• A corner or weld creates a micro-crack

• Salt creeps under the coating at a scratch and corrosion spreads underneath

Once corrosion starts under a coating, it can travel invisibly. The outside still looks “fine”… until it suddenly bubbles, flakes, or blooms with rust.

That’s why coastal homeowners should avoid thinking in terms of “paint color” and start thinking in terms of “coating system.”

(Without the jargon)

There are different levels of protection in the market. Here’s a homeowner-friendly breakdown:

Level 1: Painted Steel (basic)

Pros: inexpensive, looks good initially

Cons: coating damage = fast corrosion in coastal air

Level 2: Better Paint Systems (primer + topcoat)

Pros: improved resistance if done right

Cons: quality varies, still vulnerable at chips and seams

Level 3: Powder Coating (electrostatic coating)

Pros: tougher finish, better abrasion resistance than many paints

Cons: can still fail if scratched and if base protection is weak

Level 4: Galvanized Protection (zinc-based protection for steel)

Pros: strong corrosion resistance base layer

Cons: appearance depends on finish; not all galvanizing is equal

Level 5: “Duplex” protection (a strong base + a durable top layer)

Pros: best of both worlds—barrier + base protection

Cons: higher manufacturing cost, but often lower lifetime cost

Important: The “best” depends on your specific exposure:

• How close are you to the ocean?

• Is your home in constant sea breeze?

• Is the install exterior or interior?

• Are you in a hurricane-prone area with more airborne salt and moisture?

If you want the SWB specifics (coatings, models, options), use the source of truth:

You can buy strong bars… and still end up with coastal failure if the screws and anchors corrode.

Why? Because corrosion often starts where metal meets metal.

Common coastal hardware problems:

• Rusted screw heads that stain walls and frames

• Frozen threads that make maintenance impossible

• Anchors that loosen over time due to corrosion and expansion

• Dissimilar metal contact causing galvanic corrosion (metal “battles” at the contact point)

This matters a lot if you care about:

• Clean look (no rust streaks)

• Long-term tight mounting

• Ability to remove, adjust, or service components later

A smart coastal shopping checklist includes:

• What fasteners are used?

• Are they coastal-rated?

• Are washers and spacers used to reduce corrosion at contact points?

• Is the mounting designed so you can inspect it easily?

SWB is designed to solve the real-world installation and maintenance problem, not just the showroom picture. For SWB mounting approach and guidance, see:

(What coastal homeowners should know)

This is one of the biggest performance decisions you’ll make.

Exterior install

Pros:

• Visible deterrent

• Can protect windows from direct tampering

Cons:

• Highest exposure to salt air, rain, and wind-driven moisture

• Coatings face more UV and abrasion

• Maintenance becomes more important

Interior install

Pros:

• Much lower salt exposure

• Coatings typically last longer

• Easier inspection and maintenance

Cons:

• Not always compatible with every window design

• Requires a clean fit to avoid interfering with window operation

Coastal rule of thumb:

If you can do interior installation without compromising functionality, it can dramatically extend the “like-new” life of your bars.

But if you prefer exterior installation for deterrence, the bars must be chosen with true coastal durability in mind.

This is where SWB’s modular approach becomes especially valuable, because you’re not locked into a one-size, one-window custom fabrication that’s expensive to replace. You’re building a scalable system.

Get the full SWB fitment and installation approach at:

Coastal homes are rarely “standard.”

You might have:

• A mix of window widths across the home

• Renovations over time

• Different frames (wood, vinyl, aluminum)

• Unique opening styles (sliders, casements, single-hung, etc.)

• HOA constraints on exterior appearance

Traditional custom metal bars can be:

• expensive to design for each window

• slow to manufacture

• difficult to adjust

• hard to replace if one section is damaged or corroded

• “all or nothing”—you replace the whole set when one piece becomes the problem

A modular system changes the game:

• You can build coverage window-by-window

• You can adjust the system to match real measurements

• If one section needs replacement, you don’t redo the whole project

• You can expand protection over time (start with the most vulnerable windows)

This is exactly why SWB exists: a modular window bar system built for real homes with real constraints.

If you want the best starting point:

Go to www.securitywb.com and use the sizing resources to plan your system.

(The Buyer’s Decision Framework)

Here’s the simplest way to choose correctly, without getting trapped by marketing:

Step 1: Identify exposure

• “Direct exposure”: oceanfront, strong sea breeze, frequent salt mist

• “Moderate exposure”: a few miles inland, coastal humidity but less salt spray

• “Humid climate”: high humidity but less salt (still corrosion risk)

Step 2: Identify installation location

• Exterior install (more exposure)

• Interior install (less exposure)

Step 3: Identify window vulnerabilities

• Ground floor windows

• Hidden side windows

• Windows near fences or climb points

• Basement windows (if applicable)

• Windows near flat roofs or ledges

Step 4: Match durability + security

You’re aiming for:

• strong structure

• a coastal-suitable protective system

• hardware that doesn’t become the weak link

• a design that doesn’t trap salt-moisture

• a solution that you can maintain without headaches

Step 5: Choose a system you can scale and maintain

That’s the modular advantage.

SWB is designed to fit this framework. The details, options, and real guidance are available at:

(Copy this and use it)

Before you buy, ask these questions:

1) What makes these bars “coastal” beyond color?

2) What is the protective strategy if the surface gets scratched?

3) What fasteners are included—and are they coastal-suitable?

4) Will the design trap water or salty moisture in corners or seams?

5) Can I inspect the mounting points easily after installation?

6) If one piece is damaged, do I replace everything or just the affected section?

7) Do the bars work with my specific window type and opening?

8) Will this installation still look clean after 12 months of salt exposure?

If a seller can’t answer these clearly, it’s a risk.

If you want a system built to answer these questions upfront, start at:

(So you can avoid bad purchases)

Let’s keep this practical:

Salt is the accelerator. It doesn’t “cause rust” by itself, but it speeds up the electrochemical process that turns steel into corrosion products.

In coastal environments, salt deposits on the metal surface and holds moisture. That moisture creates a conductive pathway. Oxygen enters the mix. Corrosion reactions happen faster.

Where does coastal corrosion start first?

Almost always in one of these places:

• fasteners (screws, bolts, anchors)

• joints (where two pieces meet)

• crevices (tight spaces where salty moisture sits)

• edges and corners (where coatings are thinner or get scuffed)

• welds (if coating or surface prep is inconsistent)

• contact points against walls or frames (where moisture can be trapped)

This is why “pretty bars” often fail in real coastal life.

The bars that last aren’t just “thicker.”

They’re engineered as a system.

(5 minutes that saves years)

Coastal homeowners don’t want a full-time maintenance project. You want protection that stays clean and strong.

Good news: coastal maintenance can be simple if you do the right things consistently.

The Coastal Rinse Routine

Frequency:

• High exposure (oceanfront or constant sea breeze): every 4–8 weeks

• Moderate exposure: every 8–12 weeks

• Humid but less salty environments: seasonally

What to do:

1) Rinse the bars with fresh water (a gentle hose rinse is often enough).

2) Focus on joints, corners, and fastener areas.

3) Let them dry naturally.

4) Inspect fasteners and edges for early signs of coating damage.

5) Touch up any deep scratches quickly (compatibility matters—use recommended touch-up products).

Why rinsing helps:

You’re removing salt deposits. You’re taking away the “accelerator.”

The Inspection Habit (the part most people skip)

Once per season, check:

• screw heads (any rust bloom?)

• seams and joints (any coating lift?)

• corners and edges (any chips?)

• mounting tightness (any movement?)

If you do those two habits—rinse + seasonal inspection—you massively extend coastal performance.

Want guidance built around a modular system that’s designed to be maintainable?

SWB resources are available at:

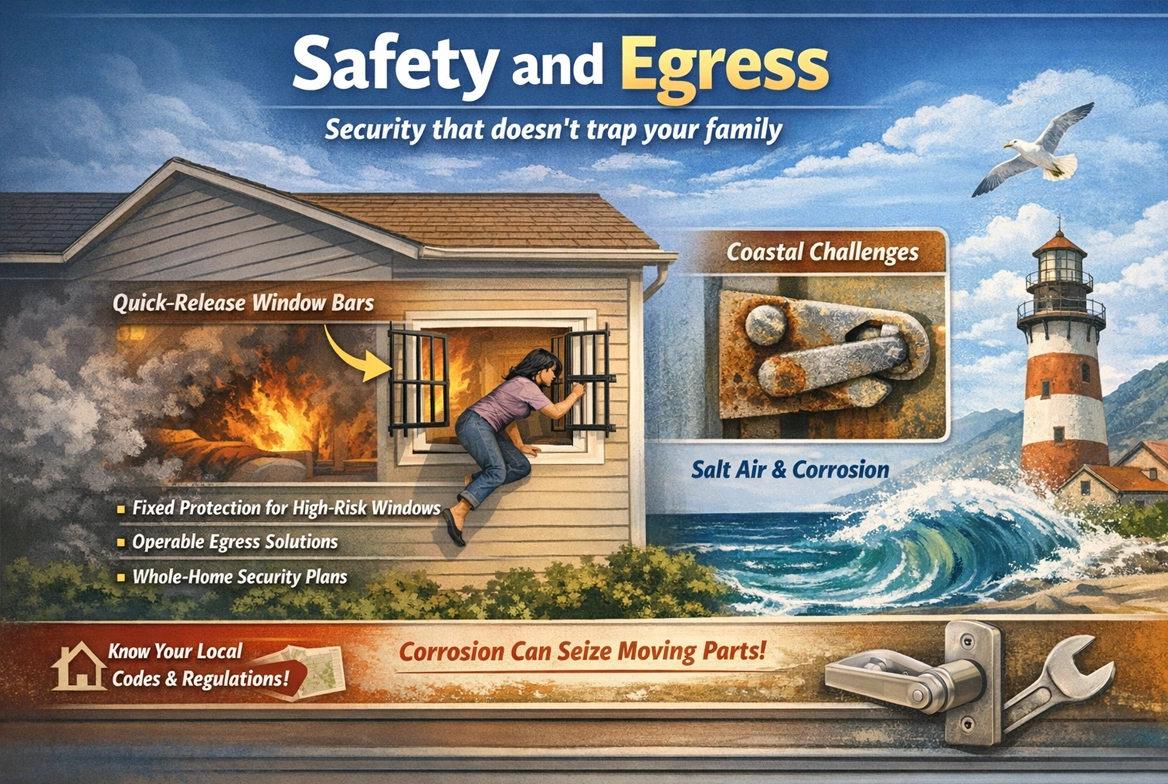

(Security that doesn’t trap your family)

This matters, and it’s often ignored in the window bar conversation.

Security isn’t only about stopping entry.

It’s also about preserving safe exit pathways when needed.

Some windows in some homes function as potential escape routes—especially bedrooms, ground floor rooms, or certain layouts.

That’s why many homeowners evaluate:

• fixed protection for high-risk windows

• operable or release solutions for specific egress locations

• a whole-home plan that balances security with common sense

Important:

Local rules and code expectations vary by location and housing type. If you’re unsure, consult local guidance for your area.

But here’s the coastal-specific truth:

If you choose an operable or quick-release solution, coastal durability matters even more—because corrosion can seize moving parts.

This is where “hardware quality + maintenance” becomes non-negotiable.

If you’re considering SWB configurations or options, confirm what’s available and appropriate for your use at:

Let’s talk about why SWB makes sense for coastal homes in real homeowner language.

Most homeowners don’t want:

• one-off custom fabrication per window

• confusing sizing

• expensive replacements if one section fails

• installs that require welding or major construction

• “hope it fits” guesswork

• a system that can’t evolve as the home changes

SWB is built to solve those exact pain points:

1) Modular by design

Instead of treating every window like a custom metal project, SWB gives you a system you can build, adjust, and scale.

2) Better fit for real homes

Real homes have different windows. SWB is meant to fit real measurements and provide a clean, consistent look.

3) Expandable protection

Start with the most vulnerable windows first. Then expand as you want. You’re not forced into an all-or-nothing project.

4) Practical replacement logic

If you ever need to replace a section, modular systems are inherently easier to service than a single welded unit that requires full replacement.

5) Designed for durability thinking

Coastal durability isn’t an afterthought. The SWB ecosystem focuses on long-term ownership—not just day-one appearance.

The best way to understand your SWB options is to use the official resources:

(Why coastal homeowners end up paying twice)

A lot of coastal homeowners experience the same expensive pattern:

Year 1:

• Buy a basic set (looks great in photos)

• Install

• Feel protected

Year 2:

• Rust starts at screw heads and corners

• Coating starts lifting or bubbling

• Bars stain the frame or wall

• Fasteners seize

• Bars look aged and “cheap” quickly

Year 3:

• Replacement becomes the only clean option

• You pay for new bars AND a second installation

That’s the hidden cost:

Cheap bars aren’t cheaper if you replace them early.

A modular approach can reduce that replacement burden because:

• you can service or replace parts rather than redoing everything

• you can upgrade step-by-step rather than tearing it all out

That’s why SWB is a smarter long-term decision for many coastal homes.

See current options and details at:

Use Case 1: Oceanfront Home (high salt exposure)

Priorities:

• top-level durability

• hardware that won’t become the weak link

• easy inspection and maintenance access

• exterior installs require higher durability expectations

Smart approach:

• focus on a system, not just a finish

• maintain with routine rinsing

• consider interior installs where appropriate

Use Case 2: Beach Rental / Airbnb

Priorities:

• durability + consistent clean look

• low maintenance time

• scalable protection across multiple windows

• easy replacement if a section gets damaged

Smart approach:

• choose a modular system

• use a repeatable installation strategy

• keep a simple maintenance schedule

Use Case 3: HOA-Restricted Neighborhood

Priorities:

• appearance

• consistent design across windows

• compliance with exterior guidelines

• minimal visual clutter

Smart approach:

• modular systems often allow a cleaner and more consistent look

• plan the install for “uniformity”

• confirm HOA requirements before exterior installation

Use Case 4: Mixed Window Sizes / Renovated Home

Priorities:

• flexible sizing

• no custom metalwork for every window

• ability to adapt as windows change

Smart approach:

• modular is the obvious win

• start with vulnerable windows and scale later

Coastal window bars are window security bars selected or designed to resist salt air corrosion and coastal humidity, with durable protection and hardware suited for marine environments.

They can, especially if the coating is scratched or if corrosion starts at joints and fasteners. Powder coating can be strong, but coastal success depends on the full system, not just the top layer.

Salt particles (chlorides) settle on metal surfaces and attract moisture, creating an environment where corrosion reactions happen faster.

High exposure homes may benefit from rinsing every 4–8 weeks. Moderate exposure can often rinse every 8–12 weeks. Seasonal rinses are still helpful in humid climates.

Interior installs typically face less salt exposure and may last longer. Exterior installs provide visible deterrence but require stronger durability planning.

Often the fasteners and mounting points. Corrosion commonly starts at screw heads, anchors, joints, and crevices.

Yes. Touch-up can prevent salt from creeping under a coating. Use compatible touch-up materials and inspect routinely.

Often, yes—because modular systems can be adjusted to real window sizes, scaled over time, and serviced more easily if one section is damaged.

Well-installed, clean-looking bars can add perceived security value. Rusted or poorly maintained bars can do the opposite.

They can be, but homeowners should consider egress needs and local requirements. If a bedroom window is considered a potential escape route, think carefully about the solution and maintain operable components if used.

Use official sizing guidance and tools. SWB provides planning resources at www.securitywb.com

All official information is at www.securitywb.com

Ready to protect your coastal home with a system built to fit real windows—without turning it into a custom metal project?

Go to:

• Check the SWB system

• Use the sizing resources

• Plan your modules

• Choose a setup that scales with your home

If you want window bars that stay strong and clean-looking near the ocean, don’t buy based on photos alone. Buy based on a system: durability strategy, hardware quality, smart installation, and maintainability.

SWB exists for homeowners who want:

• serious security

• real-world fit

• modular scalability

• a practical long-term solution

Your next step is simple:

Visit www.securitywb.com and build your plan.

COOKIES POLICY

Security Window Bars LLC ("SWB") uses cookies and similar technologies to improve your browsing experience and enhance the functionality of our website www.securitywb.com (the “Website”). This Cookies Policy explains what cookies are, how we use them, and how you can manage your cookie preferences.

By using our Website, you agree to our use of cookies as described in this policy.

Last Updated: 01/01/25