Galvanized Steel vs. Carbon Steel is the material decision most homeowners make without realizing it. Two window-bar products can look nearly identical in a store: both are “steel,” both feel heavy, and both promise security. But after a humid season, a coastal summer, or even one careless scratch during installation, those two products can age in completely different ways. This guide explains Galvanized Steel vs. Carbon Steel for homeowners in the USA and Mexico—why paint-only carbon steel often rusts from the inside out, why galvanized steel resists that failure pattern, and why Security Window Bars (SWB) builds on galvanized steel plus an electrostatic finish for long-term performance.

If you only remember one line, let it be this: Galvanized Steel vs. Carbon Steel is not about what looks strong on day one—it’s about what stays strong and functional after years of real-world weather, scratches, humidity, salt air, and daily life.

In Galvanized Steel vs. Carbon Steel, both options start with steel, and both can be structurally strong. The difference is the protection system:

So the real question is not “Are these bars steel?” It’s “What happens when the finish gets damaged?” Because in real life, finishes get damaged—especially during installation.

In the aisle, coatings look perfect. Under sunlight and rain, coatings face:

That is why Galvanized Steel vs. Carbon Steel is the difference between “installed once and forgotten” and “installed once, then maintained forever.”

Before you can win the material game, you need to understand what rust is—without the textbook overload.

Rust is what happens when iron in steel reacts with oxygen and water (and often salts) to form iron oxides. That reaction is essentially an electrochemical process. It is accelerated when:

So in Galvanized Steel vs. Carbon Steel, the key issue is how quickly moisture and oxygen can reach the steel, and what happens after they do.

Even in dry areas, steel can corrode:

In other words: corrosion is not only a coastal problem. It’s a time problem.

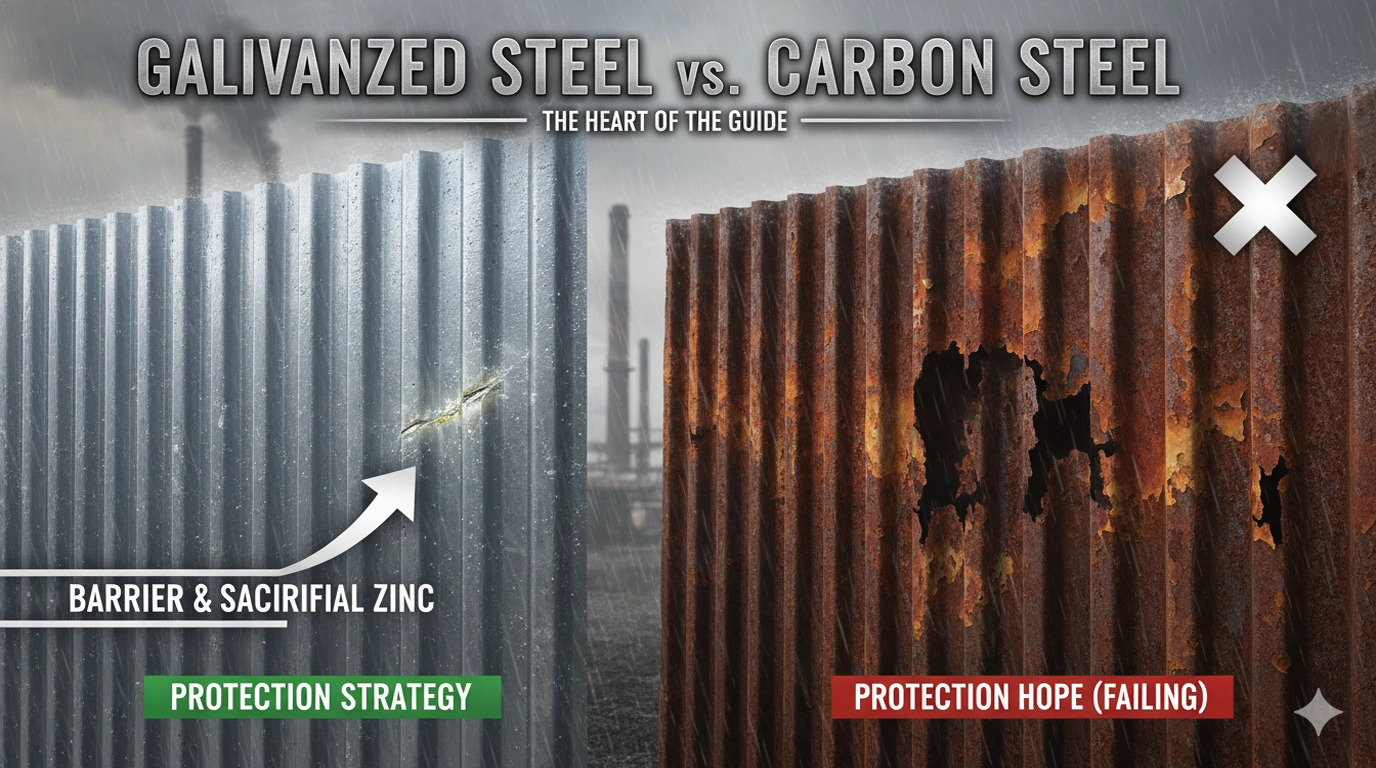

This is the heart of the entire guide. Galvanized Steel vs. Carbon Steel is really protection strategy vs protection hope.

Carbon steel bars are commonly coated. If the coating remains intact, it blocks moisture and oxygen.

But barrier-only protection has one fatal weakness:

Once the coating is breached, the steel is exposed.

That breach can be tiny:

And once the breach exists, corrosion begins at the exposed point and can spread underneath the coating.

In Galvanized Steel vs. Carbon Steel, galvanized steel is different because zinc is not only a barrier—it can also provide cathodic (sacrificial) protection.

In plain language:

This does not mean galvanized steel never corrodes. It means it’s engineered to protect the steel in the real world, where scratches are normal.

If you want to explain Galvanized Steel vs. Carbon Steel in one sentence:

That one sentence explains why the long-term outcome looks so different.

You will see phrases like:

For homeowners, the point of mentioning a standard like ASTM A123 is not to memorize it. The point is: it suggests the galvanizing is a defined process with a performance intent, not a vague marketing claim.

In Galvanized Steel vs. Carbon Steel, you want to know:

Not all “zinc” mentions are equal. A thin zinc-rich coating or spray can help, but it’s not the same as robust galvanizing processes typically associated with long-term outdoor performance.

If you want durability, treat Galvanized Steel vs. Carbon Steel like this:

Ask the seller or manufacturer:

“Is the steel galvanized, or is it carbon steel with powder coat only?”

If the answer is unclear, you already have your answer.

Homeowners usually don’t notice rust at first. They notice:

That is often underfilm corrosion, where corrosion develops beneath a coating, lifts it, and expands the damaged area.

Rust products can occupy more volume than the original steel surface. That expansion pushes upward, breaking the bond between steel and coating. Once the coating lifts even slightly, it becomes easier for moisture to move under it, spreading corrosion.

That’s why a single scratch on carbon steel can become:

In Galvanized Steel vs. Carbon Steel, this is why paint-only bars can “fail” even if the steel underneath is still thick. The coating system collapses, and the product starts aging fast.

Because zinc protects steel at scratches, galvanized steel reduces the “seed point” corrosion that initiates underfilm creep. Again: not perfect, but far more tolerant of normal damage.

So if you’ve seen bars that look great for 6–12 months and then suddenly degrade, that pattern is classic Galvanized Steel vs. Carbon Steel reality.

If you live in coastal or near-coastal regions, you already know the pain:

This is the coastal corrosion tax—and it’s not a feeling. It’s chemistry.

Coastal air often contains salt aerosol. Salt increases water conductivity, which accelerates corrosion reactions. Humidity keeps surfaces wet longer, and wind carries abrasive grit that damages coatings.

That’s why Galvanized Steel vs. Carbon Steel becomes the most important choice in places like:

USA examples

Mexico examples

In a coastal zone, “powder coat only” often becomes a maintenance plan, not a product feature.

That’s why Galvanized Steel vs. Carbon Steel should be treated as a requirement, not an upgrade, in salt-air regions.

Electrostatic finishing is often about uniform application and consistent appearance. It can:

But here’s the key: even a premium finish works best on a corrosion-resistant foundation.

That’s why SWB uses:

So the smartest version of Galvanized Steel vs. Carbon Steel is:

Corrosion almost never starts in the middle of a perfectly coated flat surface. It starts where protection is weakest:

When you drive a screw through coated carbon steel, you create:

If the underlying steel is carbon steel, that point can start rust. That’s why Galvanized Steel vs. Carbon Steel matters specifically at fasteners.

Weld zones can have:

Again, Galvanized Steel vs. Carbon Steel becomes visible at joints first.

If a product looks perfect in the middle but rusts at screws, corners, and seams, you’re seeing the normal failure pattern of paint-only carbon steel outdoors.

This section matters because corrosion doesn’t just look bad—it can change how parts move.

If you install any system with moving components (for example, an egress-friendly quick-release design in a bedroom or habitable basement), corrosion can cause:

So Galvanized Steel vs. Carbon Steel is not only about “ugly rust.” It can be about whether a release mechanism stays smooth over time.

If a window is part of emergency escape, the security solution must not turn it into a trap. That is why SWB offers an egress-minded option (like Model A/EXIT) for rooms where escape must remain possible.

Material choice supports safety by keeping components from seizing—another reason Galvanized Steel vs. Carbon Steel is a life-safety decision in the right rooms.

Many homeowners focus on “price today.” But the long-term cost is:

With paint-only carbon steel bars, the common pattern is:

That’s not “low cost.” That’s deferred cost.

In Galvanized Steel vs. Carbon Steel, galvanized steel supports the lifestyle homeowners actually want:

That’s exactly why SWB builds with galvanized steel plus electrostatic finish—because security that looks degraded stops feeling like an upgrade.

Labels and descriptions to look for

Red flags that often mean carbon steel + barrier only

Questions to ask

If the seller can’t answer #2 clearly, you’re seeing why Galvanized Steel vs. Carbon Steel matters.

Quick checklist (printable)

Next step: size your windows the smart way

Use the SWB Module Calculator Tool to get the right configuration for your openings:

If you’ve ever bought outdoor metal hardware that looked great in month one and ugly in month twelve, you’ve already lived the lesson of Galvanized Steel vs. Carbon Steel. Paint-only carbon steel bars can be strong, but their corrosion defense often collapses the moment real life scratches the coating. Galvanized steel is built for reality: zinc protection helps defend the steel even after damage, reducing underfilm corrosion, peeling, and long-term degradation.

That’s why SWB uses galvanized steel plus an electrostatic finish—because your home security should stay strong, clean, and dependable for years, not seasons.

COOKIES POLICY

Security Window Bars LLC ("SWB") uses cookies and similar technologies to improve your browsing experience and enhance the functionality of our website www.securitywb.com (the “Website”). This Cookies Policy explains what cookies are, how we use them, and how you can manage your cookie preferences.

By using our Website, you agree to our use of cookies as described in this policy.

Last Updated: 01/01/25